CO-CURRICULAR ACTIVITIES

Garuda poly flex pvt ltd

Place: Garuda Polyflex Foods Pvt Ltd,

Bommasandra – Bangalore.

Date: 26-02-20 SEMESTER: IV A, B & C

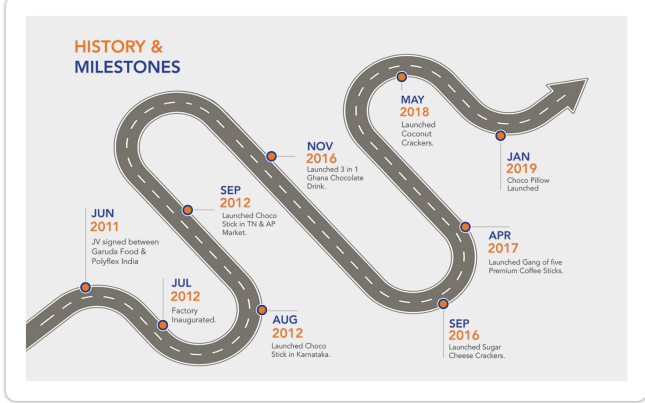

About the Company Garuda Polyflex Foods Pvt. Ltd is a joint venture established in the year 2011 between Garuda Food of Indonesia and the Polyflex Group of India. Garuda Food has a strong portfolio in food and beverage, offering an extensive and innovative range of snacks, confectioneries, biscuits, liquid milk drinks, fruit flavored drinks and juices that are widely distributed across many countries in Asia, Europe, Middle East, Africa, North America, Australia and Pacific Ocean nations.

Vision

Build a sustainable FMCG business in India with brands that create new market; constantly ushering in new consumption experience and leveraging our Global Portfolio.

Mission

We are a transformation making company creating value to society by values of caring, team work, continuous improvement and high degree of customer delight

The process carried out by the Garuda Polyflex Foods Pvt Ltd.

Garuda Polyflex Foods Pvt Ltd employee explained us the complete process about how the gone mad sticks are manufactured as well as how the packing takes place. We the students were organized in a batch of 30 members to enter into the manufacturing area. As soon as we entered we were provided with mask, hair gloves, and a specially made plastic bags to cover up our shoes so that the dirt from it won’t be entered into the manufacturing area. Then we were guided by the employee who was working for the production process. He introduced us to the various machines that was there in the production place. He explained us about the entire process starting from how the mixture of the batter is made still how the packing and storage is done. The process is started with the raw materials arriving from Indonesia and this raw material are then added up to a machine which mixes the entire raw materials and forms

a batter the batter are then stored in a huge container which can with take upto 500kgs there where totally 4 such containers. Then the batter is added up to the container were it bakes them into a chocolate stick. The baked chocolate sticks are then transferred to a place where the inner filling of the sticks flavors are added. They are totally making 4 such flavors like choco stick, strawberry stick, cashew mithai and finally premium coffee. Once the filling takes place then it is transferred to a container and this containers are the transferred into packing department. The packing happens in two ways 1)primary packing 2)secondary packing. Primary packing is where the sticks are placed in a auto packing container. This container packs the sticks into there wrappers and then are boxed 24 units in a box. Secondary packing is where this 24 units box are packed into a much larger box which are used for delivering to different outlets. This boxes are then stored in there huge warehouse. The manufacturing units totally produce 8,50,000 units per day. The Garuda Polyflex Foods Pvt Ltd only produces the gone mad wafers and the other products of gone mad are directly received from the Indonesia which are transported from this place. This was the entire process of how the company manufactured, stored and transported there products.

Learnings from the Visit

1. Cleanliness

GP always aims to maintain a clean and hygiene environment as they are dealing with a consumable commodity and hence when we visited the factory we were asked to wear face masks, hair masks and special covers to cover our shoes to prevent any dust from entering the production process.

2. Employee

Welfare GP has its own mess where the employees are served meals. This goes a long way in building employee morale and ensures that the employees are always happy and satisfied which results in effective and efficient production volumes and lower attrition rate.

3. Quality of materials

GP sources its raw materials from the best of the locations. For eg., it sources its cocoa and crackers directly from Indonesia and supplies across the country. This ensures that the best quality product reaches the consumer

4. Storage and Warehouse

GP has a very large warehouse where it stores its 8.5 lakh choco stick that it produces every day. It comprises of high racks and stands to save space and speed up the loading process hence reducing the lead time from getting an order and dispatching it.

5. Diversity

GP has quite an extensive product portfolio which helps meet the demand of all type of consumers and hence stay competitive. It imports it crackers from Indonesia and produces the other products in its own plant.